I’m trying to retrofit my existing wired doorbell so I can get a push notification when it rings. After that, I’ll have a webcam at the front door so I can include a link to either an image or the live feed.

I’ve got the whole cloud push notification part figured out which leaves the hardware challenge. I don’t want to make a new doorbell. I just want to detect the existing one’s ring.

I can think of two ways.

- “Listen” for it. I’ve got this mic. Perhaps I can just listen for what would be a wildly loud sound if I put sparkcore inside the doorbell enclosure(there’s room).

- Measure the AC voltage powering the actuator that rings the bell.

- Toss the doorbell and buy a new wireless one and figure out how to tap into it. I’m sure there will be a simple way to measure a DC voltage value on it somewhere.

The second option is the way I’d like to go because it seems more direct and I’d like some experience with the analog inputs on the spark core. If it turns out to be too difficult, I’ll fall back on option 3.

Here’s a pic of the internal of the doorbell. The actuator punches out and hits the metal bars on either side to create the chime.

AC Voltage at 2 and 3 is 10VAC relative to GND(white wires).

When the doorbell rings the voltage at 2 drops to 0VAC while the button is pressed and returns to 10VAC when it’s released.

AC Voltage at 1 is always 0VAC

Here are my questions. I’d appreciate some input.

-

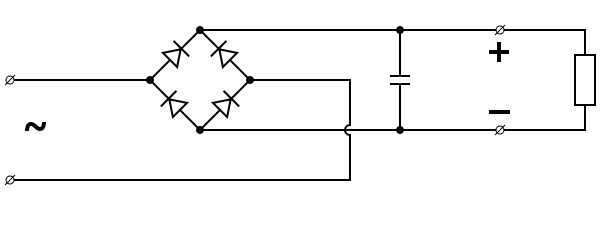

How can I read 10VAC from the spark core? Can I just put a big enough resistor between 2 and an analog input pin to drop it low enough for the core to handle or do I need something more involved?

-

Is it possible to convert 10VAC to 5VDC so I can power the core off the consistent 10VAC on 3? This would be the perfect solution to not have to deal with batteries.

Any input would be appreciated.