I am excited about the many potential uses for the Particle platform and have been working on an industrial controls use case for the past year or two. The idea started as a way to augment the existing 70’s era electro-mechanical control systems still used in most parks with a connected monitoring solution. That way, when the “low water level” alarm went off or when a pump was called to pump, it could inform the maintenance staff thereby reducing staff labor costs and improving the reliability of the system. Here is a picture of one of these old systems with a Particle Electron based monitor.

I put a few of these in a local park over a year ago and the park staff has been very pleased. This takes me to the next step of moving from monitoring the water systems to (co-)controlling them. The idea is to use the Particle controllers for the well heads and a PLC / Particle combination for the water storage controllers. I am sharing this project for two reasons: 1) I might get some free advice  and 2) This might get folks thinking about new use cases for the Boron.

and 2) This might get folks thinking about new use cases for the Boron.

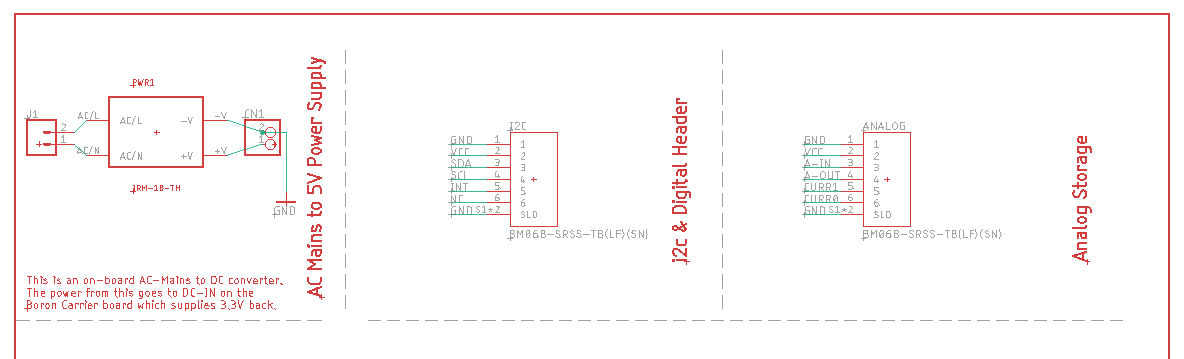

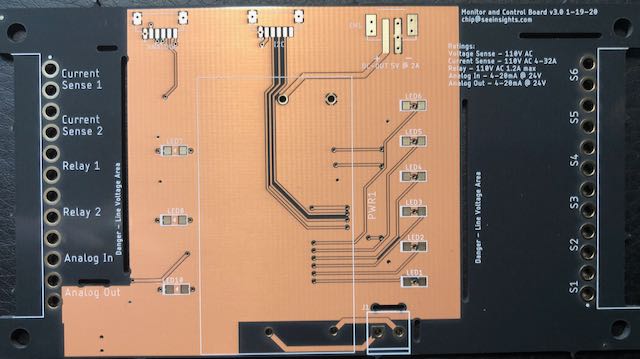

Control board specs:

- Powered by 110v-240v for both the sensor board and the Boron

- Six digital line sensing inputs (110V)

- Two current sensing inputs

- One 4-20mA controller

- One 4-20mA receiver

- Two digital outputs (110V / 1.2A)

Caveat - If you build one of these, please be careful as the high-voltage parts (indicated on the board) are dangerous. OK CYA complete.

It will connect to the Boron using two 6-pin JST - SH cables (and a power connection for the Boron carrier).

I have received my boards back from OSHPark and will be assembling and testing them this week.

What do you think?